Details

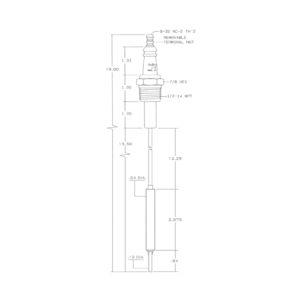

Nozzle Line Electrode Assembly – Self-centering, delivers oil to the nozzle, high voltage electricity to the electrodes; static plate controls and evens out air flow to the head for smooth, efficient combustion.

Flame Retention Head – Multiple head styles available to match flame characteristics to individual appliance designs.

Motor – Continuous duty permanent split capacitor (PSC), built for daily hard use and years of trouble free operation.

Ignition Transformer – 10,000 V/23 mA secondary positively and smoothly ignites fuel. Electrically balanced and shielded. No TV interference. Designed for heavy duty continuous operation.

Connector Tube Fitting – Special Beckett, high quality flare fitting.

Burner Housing – Sturdy die cast, precisely machined aluminum housing aligns pump and motor for smoothest operation and longest coupling life.

Features

Capacities

- 0.40 to 3.00 gph

- 56,000 to 420,000 BTU/hr input

Fuels

- ASTM D396 FOR #1 & #2 Heating oil

- ASTM D396 for B6 – B20 Biodiesel blends

- ASTM D975 for Diesel fuel, Renewable diesel

- Biodiesel blends of D396 & D6751 to B100

- CAN / CGSB -3.2 for Heating oil Types 0, 1, and 2

Fuel Unit

- Beckett CleanCut®: Single or Two Stage standard

Motor

- 1/7 HP 3450 rpm PSC type

Igniter

- Beckett PowerLight® Solid state

- Rated for continuous duty

Control

- Beckett GeniSys® Model 7565

- myTechnician app for programming and diagnostics

Dimensions (Standard)

- Height: 11-1/2″

- Width: 12-7/8″

- Depth: 6-9/16″

Dimensions (with Cover)

- Height: 12-1/2″

- Width: 15″

- Depth: 9-1/4″

Electrical Characteristics

- Power Supply: 120 VAC, 60Hz, Single Phase

- Operating Load:

- 5.8 Amps maximum @ 120 VAV

- 240 VAC – Available (Contact factory)

Flame Retention Heads

Flame retention head shape and help regulate the combustion process. Beckett has a wide selection of options to obtain the best performance in any application.

Available Models

| Chassis | Primary Control | Fuel Unit | Bio-Fuel Compatibility |

|---|---|---|---|

| BR100 - AFG | GeniSys® 7565 with programmable pre and post purge | PF20323 - Single Stage | Up to B100 / R100 |

| BR200 - AF | GeniSys® 7565 with programmable pre and post purge | PF20323 - Single Stage | Up to B100 / R100 |

| B2005 - AFG | GeniSys® 7565 with programmable pre and post purge | PF20422 - 2-Stage | Up to B20 |

Accessory: Contractor Tool 52082 and Mounting Bracket 33023

Available Accessories

| Part Number | Description |

|---|---|

| 5432 | Adjustable Flange & Gasket |

| 5850 | Split Flange & Gasket |

| 5685 | Pedestal Mounting Kit |

| 5606 | Pedestal Mounting Kit — Extended Pedestal Kit for 8” - 13” above floor |

| 5207301U | Burner Cover Kit with Split Mounting Plate — sound-reducing and tamper-resistant |

| CAK-APU | Air Boot Kit with Air Proving - Must use with 7565 GeniSys Control |

| CAK-APU | Air Boot Kit with Air Proving - Must use with 7565 GeniSys Control |

| CAK-APU | Air Boot Kit with Air Proving - Must use with 7565 GeniSys Control |

| 51621 | Start Helper - smoother light-off for cold fuel conditions |

Available Accessories

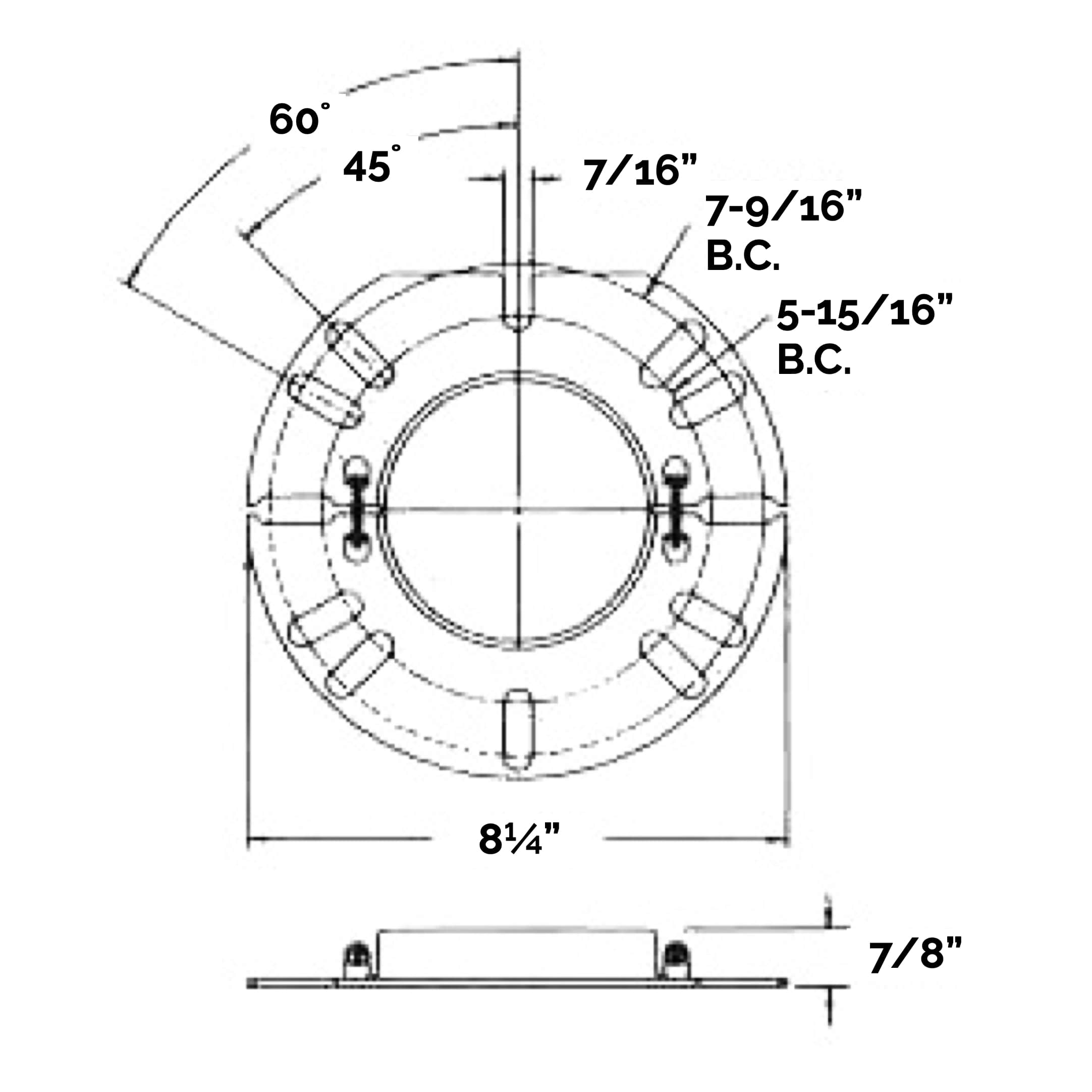

Adjustable Mounting Flange Kits

5432 or 5850

No. 5850 is a two-piece split flange. No. 5432 is a one-piece flange. Both kits include a flange mounting gasket.

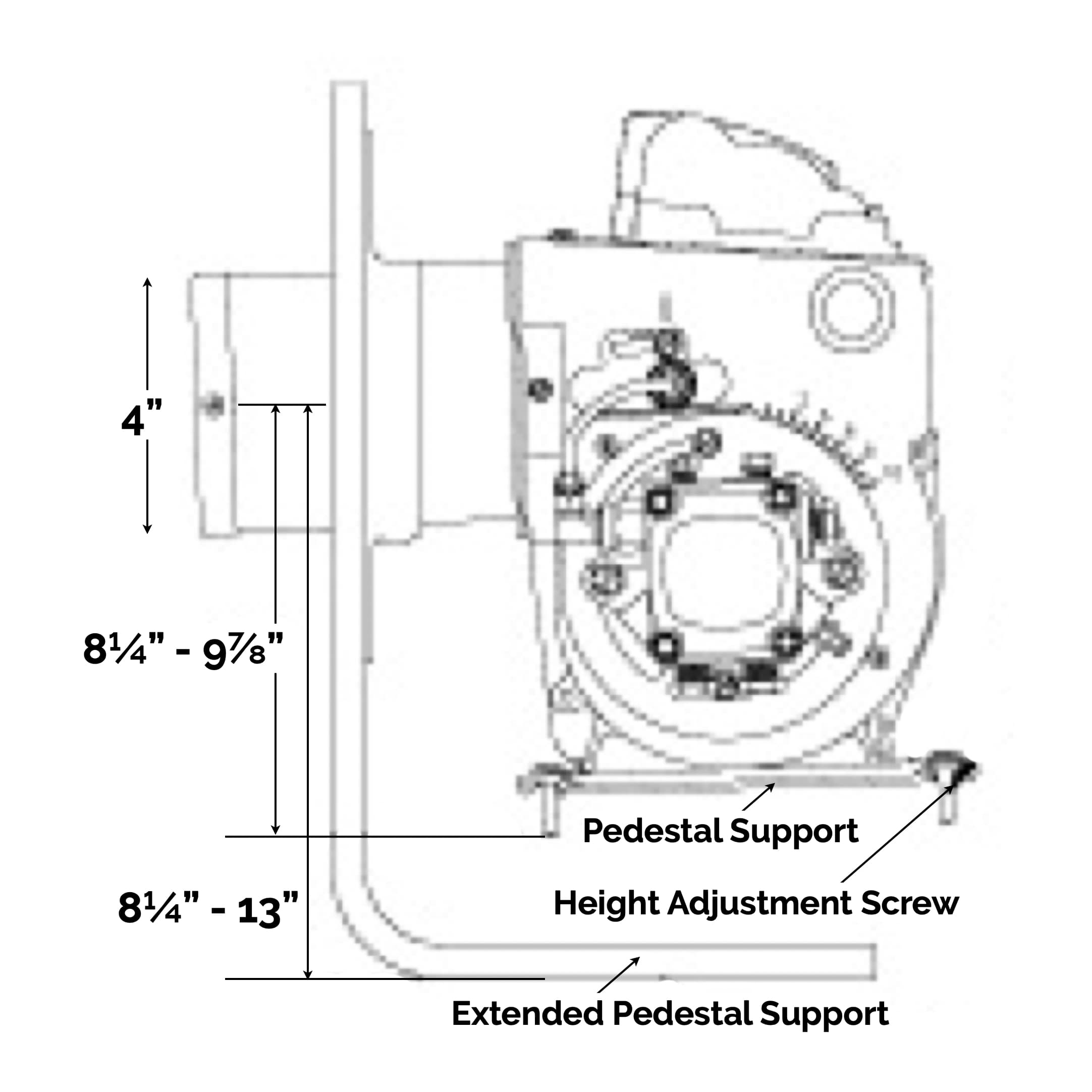

Optional Supports

5685 or 5606

No. 5685 Pedestal Kit – For conversion applications where no mounting flange is required.

No. 5606 Pedestal Kit Extended – Provides elevation from 8-1/4″ to 13″.

Air Boot Kit

51747

Includes Air Boot, Vacuum relief damper, and OA Hood

Air Tube Combinations

| Firning Rate Range - GPH | Burner Head | Useable Length - Tube | |||||||||

| 4-1/2" | 5" | 5-3/8" | 6-5/8" | 7" | 7-1/4" | 9" | 10-1/2" | 13" | 16" | ||

| Less Head | - | AF44 | - | AF53 | AF65 | - | AF72 | AF90 | AF104 | AF130 | AF160 |

| 0.40 - 0.75 | F0 | AF44XR | - | AF53XR | AF65XR | - | AF72XR | AF90XR | AF104XR | AF130XR | AF160XR |

| 0.75 - 1.25 | F3 | AF44XN | - | AF53XN | AF65XN | - | AF72XN | AF90XN | AF104XN | AF130XN | AF160XN |

| 0.85 - 1.35 | F4 | AF44WH | - | AF53WH | AF65WH | - | AF72WH | AF90WH | AF104WH | AF130WH | AF160WH |

| 0.85 - 1.65 | F6 | AF44YB | - | AF53YB | AF65YB | - | AF72YB | AF90YB | AF104YB | AF130YB | AF160YB |

| 1.10 - 2.00 | F12 | AF44XO | - | AF53XO | AF65XO | - | AF72XO | AF90XO | AF104XO | AF130XO | AF160XO |

| 1.65 - 2.50 | F22 | AF44XP | - | AF53XP | AF65XP | - | AF72XP | AF90XP | AF104XP | AF130XP | AF160XP |

| 2.50 - 3.00 | F31 | AF44XS | - | AF53XS | AF65XS | - | AF72XS | AF90XS | AF104XS | AF130XS | AF160XS |

| AFG Burner Only | |||||||||||

| 0.40 - 1.00 | L2 | - | AFG50MBSS | - | - | AFG70MBSS | - | AFG90MBSS | - | - | - |

| 0.50 - 1.10 | L1 | - | AFG50MPSS | - | - | AFG70MPSS | - | AFG90MPSS | - | - | - |

| 0.75 - 2.75 | V1 | - | AFG50MDSS | - | - | AFG70MDSS | - | AFG90MDSS | - | - | - |

Downloads & Links

Additional Resources

Warnings (prop65)

Warranty

Please note, all warranty claims must be initiated through an authorized Beckett supplier/distributor. Distribution policies will not allow Beckett to directly handle warranty claims with installers and/or consumers.